Version

Available in lengths up to

Safe Distribution of Drinking Water

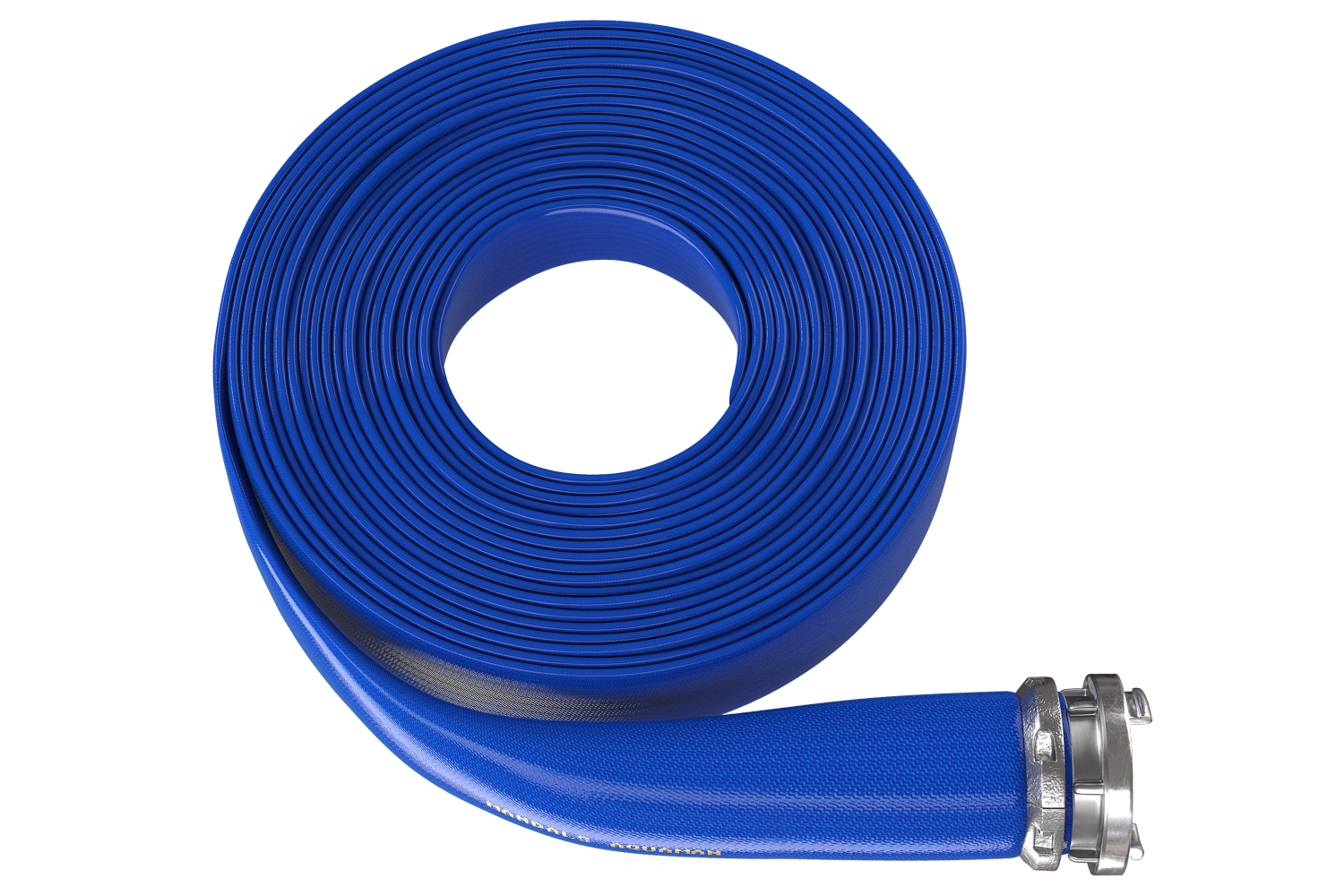

Mandals Aquaman is a lightweight lay-flat hose designed to transfer large volumes of liquids with high working pressures. In addition to its premium abrasion resistance, the hose is designed, tested, and certified for potable water transfer.

Made to Perform

Designed to meet all the needs of customers for drinking water transportation, Mandals Aquaman has been designed to provide the most efficient, economical, and easy-to-install system available.

Explore Mandals Aquaman

Mandals Aquaman

Mandals Aquaman

Product Specifications

Primary Uses & Applications

- Safe transport of drinking water

- Potable water applications

- Water Bypass

Color Options

- Blue (standard)

Lengths and Diameters

We offer a range of diameters and lengths for this hose, depending on the version. The diameters range from 25mm to 305mm, and for some diameters, the hose can be delivered in lengths up to 700m.

Operating Temperature

The hose has been developed to perform in different weather and environments, with an operating temperature from -50°C to + 75 °C ( -58°F to +167°F) for pure water.

Valid Certificates

North and South America

Germany

Germany

Poland

UK and Ireland

Aquaman

| INTERNAL DIAMETER | WALL THICKNESS | WEIGHT | BURST PRESSURE | TENSILE STRENGTH | |||||

| Inch | mm | Inch | mm | Lbs / Ft | Kg / m | Psi | Bar | x 1000 Lbs | Tons |

| 1 | 25.4 + 1.6 | 0.07 | 1.9 | 0.13 | 0.20 | 725 | 50 | 3.3 | 1.5 |

| 1 1/2 | 38.0 + 1.6 | 0.08 | 2.1 | 0.20 | 0.30 | 655 | 45 | 5.8 | 2.6 |

| 2 | 51.0 + 2.0 | 0.09 | 2.2 | 0.29 | 0.44 | 655 | 45 | 7.6 | 3.4 |

| 2 1/2 | 65.0 + 2.0 | 0.09 | 2.3 | 0.36 | 0.58 | 610 | 42 | 9.1 | 4.1 |

| 3 | 76.0 + 2.0 | 0.09 | 2.4 | 0.47 | 0.75 | 610 | 42 | 10.7 | 4.8 |

| 4 | 102.0 + 2.5 | 0.12 | 3.0 | 0.72 | 1.07 | 520 | 36 | 23.1 | 10.4 |

| 5 | 127.0 + 2.5 | 0.12 | 3.0 | 0.99 | 1.48 | 435 | 30 | 26.9 | 12.1 |

| 6 | 152.0 + 3.0 | 0.12 | 3.0 | 1.15 | 1.72 | 435 | 32 | 33.3 | 15.0 |

| 8 | 203.0 + 3.0 | 0.13 | 3.2 | 1.53 | 2.30 | 380 | 26 | 43.8 | 19.7 |

| 10 | 254.0 + 4.0 | 0.13 | 3.3 | 2.05 | 3.08 | 305 | 21 | 65.8 | 29.6 |

| 12 | 305.0 + 5.0 | 0.13 | 3.4 | 2.53 | 3.80 | 220 | 15 | 83.1 | 37.4 |

Note: Safety BP/WPis 2:1 (50%). For all non-hazard and/or non-flammable liquids. Internal Diameter stated in Inch refers to nominal hose diameter.

Pipe Rehabilitation Catalog

Want more in-depth knowledge about our liners for pipe rehabilitation? Well, we got you covered in our pipe rehabilitation catalog.

Let's Talk About Mandals Aquaman

Our dedicated Sales Managers are ready to cater to your needs and find proper solutions for your business.

Regardless of where you are in the world – we got you covered. Get in touch today.

Address

Nordre Banegate 26,

4515 Mandal,

Norway